INDEPENDENT DEALER

Downers Grove, IL | (630) 880-7199

Find Your Products

Three Tiers Of Premium Performance

SIGNATURE SERIES

100% SYNTHETIC MOTOR OIL

100% SYNTHETIC MOTOR OIL

Maximum Engine Protection

Up to 25, 000 miles or 1-year*

EXTENDED-LIFE

100% SYNTHETIC MOTOR OIL

100% SYNTHETIC MOTOR OIL

Boosted Engine Protection

Up to 20, 000 miles or 1-year*

* Whichever comes first. In normal service.

OE 100% SYNTHETIC

MOTOR OIL

MOTOR OIL

Advanced Engine Protection

OEM-recommended drain interval

ABOUT AMSOIL

Powering Your Performance

AMSOIL was created to push what’s possible. For nearly 50 years, we have pursued that goal with a relentless passion and allowed it to inform every product, technology, and service we offer.

Full Service Dealer

I had chosen the name of my business “Approved Synthetic Oil,” since an independent research laboratory had conducted a “four ball test” of various synthetic oils and AMSOIL came out on top with the least amount of wear scarring in comparison to all the other oils. I had an on-going business relationship with a PhD Mechanical Engineer, who was associated with the Society of Automotive Engineers (an expert both with mechanics and vehicles) and also a PhD Metallurgical Engineer (an expert with metals). I consulted with these gentlemen to independently determine the value of the four ball test. They both informed me that the four ball test met the standard ASTM D 4172-94 (which included both the ANSI standard B3.12 and the ASTM standard D 2266), so it was considered the "gold standard of testing" to determine an oil’s ability to prevent metal degradation inside the engine.***

My eventual dealership began on a journey "to experiment on my own" with using various synthetic oils from different manufacturers (such as Pennzoil, Valvoline, Castrol, Mobil 1 and finally AMSOIL) to find the very best. After I learned about the value of the “four ball test” from the aforementioned PhD Engineers (that indicated AMSOIL was the clear winner), I eventually decided to give AMSOIL an eventual try. The day that I drained out the Mobil 1 and put AMSOIL into my crankcase, I proceeded to take my car on my usual test drive. What astonished me was the incredible rush of performance my car had experienced together with my engine running smoother and quieter, in comparison with all the other oils! I was instantly sold on AMSOIL (which was the first oil in the world to meet the service requirements of the American Petroleum Institute in 1972). From that point, I only used AMSOIL in my vehicles and in my company cars. I then became a Preferred Customer (PC) in 2006 and after a few years, I then became a Dealer.

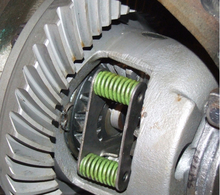

*** The four ball test involves inserting 4 brand new metal ball bearings in a special machine for each test (with three of the metal balls firmly clamped on the bottom of the machine forming a "triangle." Then a chosen oil is used to bathe the bearings, where the bearings are heated to 150 degrees C (302 degrees F), which is much hotter than the normal operating temperature of an engine. The 4th metal ball is inserted half way inside the shaft of the machine, which is then positioned against the top of the other three stationary balls (located in the center of the triangle). The top bearing is then spun at high speeds against each of the three stationary bearings during this punishing test to determine the extent of wear scarring on the bearings after the testing. This test demonstrates the sliding motion that could simulate the same conditions found inside an engine (for example, pistons sliding against the stationary cylinders of an engine block).

Jim Norris

Downers Grove, IL

(630) 880-7199